Replacement of FFU purification unit in LCD industry clean factory

LCD products have extremely strict requirements for indoor air environment and quality during the manufacturing and production process, mainly controlling particles and floating dust. At the same time, strict regulations are also made for the temperature, humidity, fresh air volume, noise, etc. of the clean room environment.

The surface of the glass substrate is coated with a transparent conductive layer of In2O3 or SnO2, namely an ITO film layer, which is processed by photolithography to form a transparent conductive pattern. If there is dust accumulation, it will be very obvious and even cause the device to be scrapped.

According to the Federal Standard (FS) 209E issued by the US federal government, cleanrooms can be classified into six levels: Level 1, Level 10, Level 100, Level 1000, Level 10000, and Level 100000. It needs to reach level 10. The standard for a level 10 cleanroom is that the indoor air should not contain more than 350 dust particles larger than or equal to 0.1 μ m per cubic foot, 30 dust particles larger than or equal to 0.3 μ m, and 10 dust particles larger than or equal to 0.5 μ m.

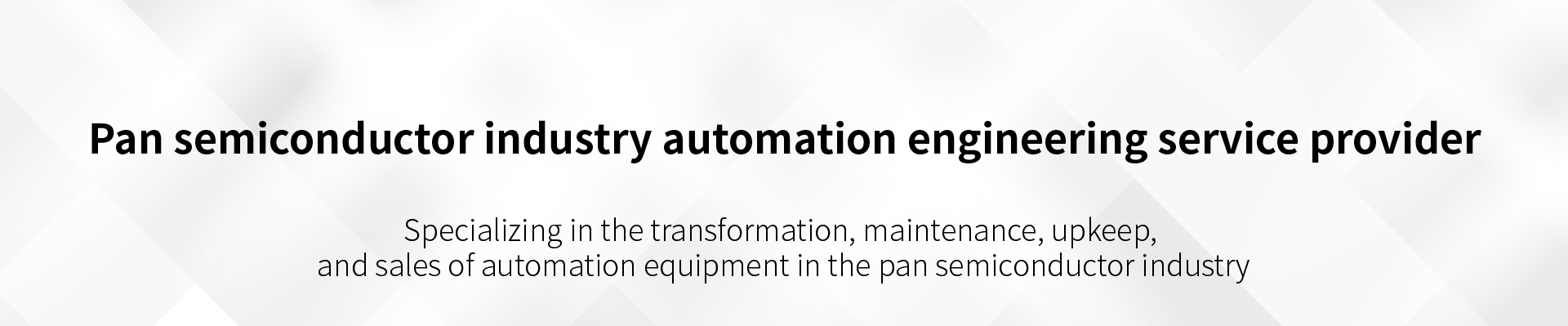

To achieve the standard of Class 10 cleanroom in LCD industry factories, purification equipment is needed, and the most common one is the FFU purification equipment. FFU stands for Fan Filter Units, which means fan filter units. It is a self powered end air supply device with filtering function; The fan sucks in air from the top and filters it through a HEPA high-efficiency air filter. After filtering, the clean air is evenly sent out from the air outlet, providing clean air and particle filtration control for a clean environment.

The air exchange rate in a typical LCD cleanroom is around 30 times per hour. If the FFU purification unit malfunctions, the dust content of the incoming air will be higher, ultimately leading to a higher dust content in the LCD cleanroom and affecting the normal operation of LCD production.

Guangke Intelligent has rich experience in repairing and maintaining purification equipment, and can repair components of FFU purification units such as motors, control components, and airflow balancing devices